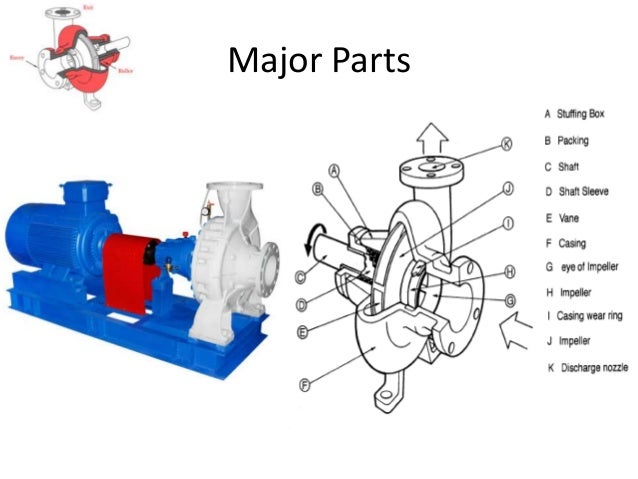

Components of pump

"Components of pumps" are something more important in all types of pumps, we will look for centrifugal pump components. pump is a device which work to lift the liquid from down to up, as we know we can not transfer transfer liquid from bottom level to upper level for that we need a pump. Centrifugal pump mainly consist a rotating element called impeller which help to pass the liquid and which result in the increase of pressure energy of liquid.

A centrifugal pump consists of the following parts, which are main components of pumping systems in centrifugal pump.

- Impeller

- Casing/Chamber

- Shaft

- Stuffing box/Mechanical seal

- Bearing

- Coupling

- Suction/Discharge nozzles.

|

| Image from Slideshare.net via https://image.slidesharecdn.com/basicsofpumppresentation-140426101650-phpapp02/95/basics-of-pump-10-638.jpg?cb=1408848820 |

Centrifugal pump parts

1. Impeller

The impeller is the most important part of the pump and a very essential component of pump for the pump performance.

It is a main rotating part that provides the centrifugal acceleration to the fluid.

Types of impeller

- Closed (Shrouds or sidewall enclosing the vanes)

- Open (No shrouds or side wall to enclose the vanes)

- Semi open (Only one side shrouded)

|

| Image from what is piping via https://static.whatispiping.com/wp-content/uploads/2020/08/Impeller-Types.png |

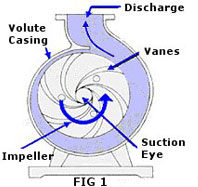

2. Casing/Chamber

Casing is a receptacle for enclosing the impeller both at the suction and delivery end so as to form a pressure vessel.

Casing also provides supporting and bearing mediums for the shaft and impeller.

Casing are of two types

- Volute Casing

- Diffuser Casing

|

| image via https://www.kiwipumps.com/images/centrifugal_pumps_fig1.jpg |

3. Shaft

Shaft is a component which carries all the rotating pump parts and also provide power to the impeller. The Shaft has to withstand the rotating rotating torque, axial and radial thrust. The deflection in the shaft during operation should be less the minimum clearance between the rotating and stationary parts.

Shaft material is selected based on below points.

- Critical Speed

- Endurance Limit

- Corrosion resistance

- Notch Sensitivity

4. Stuffing Box / Mechanical seal

Mechanical seal or shaft seal has a stationary part or face which matts with the rotating face very smoothly under pressure exerted by a spring, which gets energy partially by precompression given annually and from pressure energy of liquid.

5. Bearings

Bearing are the mediums, which keep the shaft or rotor in correct alignment with its stationary parts under the action of axial and radial bearing.

Bearings, which are designed to take radial thrust only, are called line bearing and those designed for axial thrust are called thrust bearing.

Types of bearings

- Bush Bearing

- Ball/Roller Bearings

6. Coupling

Coupling are devised used for connecting pump with the prime movers or we called it as motors. Its Mechanical equivalent of a fuse.

Types of coupling

- Rigid Coupling

- Flexible Coupling

7. Suction and Discharge nozzles

The suction and discharge nozzles are nothing but the parts of casing it self. Suction nozzle is which where water comes in and discharge nozzle is which where water go out.

Below are the configurations of suction and discharge nozzle

- End suction-Top discharge

- Top suction- Top discharge

- Side suction-Side discharge

Conclusion

A full article on Components of pumps. Thank you very much for reading full article.We hope you like the above information. If you have any questions you can write it down in the comment box or mail us at Mail id given below.

info.mechtrekk@gmail.com

0 comments: