Types of casing in centrifugal pump

Casing is a Receptacle for enclosing the impeller both at the suction and delivery end so as to form a pressure vessel. Casings also provide supporting and bearing mediums for the shaft and impeller assembly.

Casings are of two types :-

- Volute Casing

- Diffuser casings.

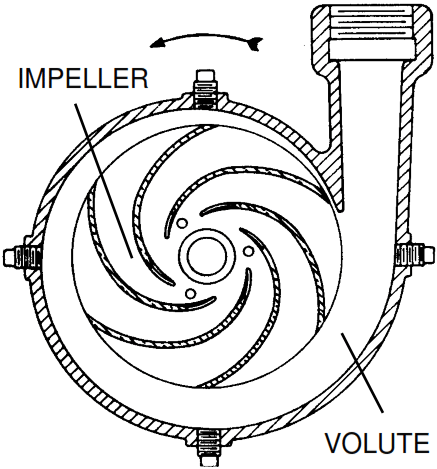

Volute casing

|

| Image by Intro to Pump via https://www.introtopumps.com/wp-content/uploads/2012/11/Volute-Pump-Assembly.png |

One the main purposes of the volute casing is to help balance the hydraulic pressure on the shaft of the pump. However, this occurs best at the manufacture's recommended capacity Running volute style pumps at lower capacity than the manufacturer recommends can out lateral stress on the shaft of the pump, increasing wear and tear on the seals and bearings, and on the shaft itself, Double volute casings are used when the radial thrusts become significant at reduced capacities.

Diffuser casing

Difference between Volute and Diffuser Casing :-

VOLUTE CASING |

DIFFUSER CASING |

|

1 |

UNSYMMETRICAL LAYOUT |

SYMMETRICAL LAYOUT |

2 |

SIMPLE CONSTRUCTION IN SINGLE STAGE PUMP |

COMPLICATED DUE TO STATIONARY ANES IN SINGLE STAGE PUMP |

3 |

RADIAL THRUST AT PART LOADS AND OVER LOADSTHRUST SHARPLY INCREASES AS HEAT INCREASES |

NO APPRECIABLE RADIAL THRUSTBUT HIGH AXIAL THRUSTS ARE THERE |

4 |

QH CHARACTERISTIC IS MODERATEAND NON OVERLOADING TYPESTABLE OPERATION AT PART LOADS |

DROOPING AND OVER LOADING TYPE QH UNSTABLE OPERATIONS AT PART LOADS |

5 |

MOSTLY HORIZONTAL AND SINGLE |

VERTICAL TYPE AND MULTISTAGE |

STAGE TYPE |

Conclusion

A full article on Types of casing in centrifugal pump. Thank you very much for reading full article. We have tried to provide as much info as possible, we hope you like the above information. If you have any questions or suggestions you can write it down in the comment box or mail us at Mail id given below.

info.mechtrekk@gmail.com

0 comments: